Ho na le liphapang tsa bohlokoa lipakeng tsaLi-curbites tsa silicon carbimele lits'oants'o tse hlakileng ka likarolo tse ngata tse kang thepa, mekhoa, ts'ebetso le litheko. Phapang ena ha e ame feela mokhoa oa eona oa ho etsa letho, empa o khetha katleho ea eona le maemo.

phapang e kholo

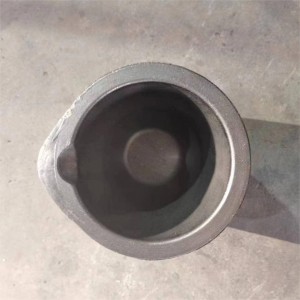

Lits'oants'o tsa graphte li entsoe haholo ka graphite ea tlhaho le ho sebelisa letsopa joaloka binder. Kopano ena e fana ka phepelo e khahlehang e sa thekeseleng le mocheso o phahameng oa mocheso, o e etsa o loketseng lits'ebetso tsa mocheso o phahameng haholo. Sebopeho se ikhethileng le phepelo e phahameng ea sebopeho sa tlhaho ea litšoantšo tsa tlhaho e ratoang haholo indasteri ea tšepe le ea hlophisitsoeng.

Ka khanye ea koae e ipapisitse le setšoantšo sa tlhaho ea tlhaho ea sebopeho sa tlhaho sa silicon e le karolo ea mantlha le karolo e phahameng ea mocheso joalo ka motsoako. Joaloka boitsebiso bo phahameng haholo, sirifon ho khahlano le ho hanyetsa haholo le botsitso ba mollo, ho lumella likhakanyo tsa carbion libakeng tse hlasimollang. Ts'ebeliso ea litšitiso tsa mocheso o phahameng hape a ntlafatsa matla a ho sithabetsa ka botlalo le ho tšoarella.

Tsamaisa Phapang

Mohato oa ho etsa lintho o qhekellang o ikemiselitse ho phehella ho hatelloa ka buka le mochini. Lits'oants'o tse nyane tse hatisitsoeng hangata li thehiloe ka mokhoa o khahlano le ts'ebetso ea likhahla tsa 1,000, 'me qetellong ea qhalana. Ts'ebetso ena ea setso, ha e sebetsa litšenyehelo, e na le meeli mabapi le katleho ea tlhahiso le mokhoa oa boleng bo fetotsoeng.

Tsamaiso ea tlhahiso ea silicon Cabite e tsitsitseng e hatetse pele, e sebelisa lisebelisoa tsa Istostatic ha li hatelle pele le mokhoa oa saense. Mahlale a Isostatic a hatella ho sebetsa a etsa khatello ea junifomo (ho fihlela ho 150 MPA), e hlahisoang ke letsoalo le phahameng le ho feto-fetoha le maemo a tlase. Ts'ebetso ena ha ea ntlafala feela e sebelisa matla a tšohanyetso, empa hape e ntlafatsa haholo ho tsitsipana le sesosa sa mocheso le sekho.

Phapang ea Ts'ebetso

Mabapi le ts'ebetso, ho na le liphapang tsa bohlokoa lipakeng tsa litlolo tsa graphite le litlolo tsa silise tsa silise. Lits'oants'o tsa Graphie li na le letsoalo la 13 Ka / cm Bophelo ba tšebeletso ea maemo a graphing hangata ke makhetlo a 3--5 le ka linako tse ling tsa silisi ea ho bolaea thepa le boholo ba silise ea silizon.

Ntle le moo, phetolelo ea mocheso pakeng tsa kahare le ka ntle ho likhato tse tloaelehileng e ka ba ea phahameng ka ho fetisisa ea sili ea silin le botsitso ba mocheso. Mae a acid le alkali ho hanela likhaba tsa silicon ho ntlafatsa haholo ho feta tsa lintho tse tloaelehileng, tse totobatsang katleho ea matla, e bolokang matla a ka bang 50% ho feta tekano e akaretsang.

Phapang ka theko

Ka lebaka la phapang ea likhakanyo tsa thepa le lits'ebetsong tsa thepa, litlolo tse sithabetseng tsa graphite le sistimi ea silise le tsona li na le liphapang tsa bohlokoa tsa theko. Ka tloaelo, mathata a ka carbion carbings a ka makhetlo a mararo a theko e phahameng ho feta tse sa tšoaneng pele. Phapang ena ea theko e bonts'a melemo ea bohlokoa ea silise ea kapola ka ho tšela lintho tse bonahalang, ho etsa lintho ka mokhoa o rarahaneng le ts'ebetso.

Ka kakaretso, le ha silicon Carbings e hloka theko e boima, ho fokotsa khatello ea bona e phahameng, le katleho ea matla ho ba etsa khetho e ngata ea lits'ebetso tse hlokahalang. Lits'oants'o tsa graphite li sebelisoa haholo likolong tse ngata tsa setso ka lebaka la litšenyehelo tsa bona tse tlase le thepa ea mantlha ea mantlha. Melemo le likotsi tsa lintho tsena tse peli tse sithabetsang li etsa qeto ea hore li loketse maemo a fapaneng a kopo.

Nako ea poso: Jun-13-2024