Isostatic Pressure Silicon Carbide Crucible bakeng sa Melting Metal

Likaroloana

(1) Ts'ebetso e phahameng ea mocheso: ka lebaka la tšebeliso ea lisebelisoa tse tala tse kang graphite e nang le conductivity e phahameng ea mocheso, nako ea ho qhibiliha e khutsufalitsoe;

(2) Ho hanyetsa mocheso le ho tsieleha ha mocheso: Ho hanyetsa mocheso o matla le ho tsieleha, ho hanyetsa ho phunyeha nakong ea ho pholile ka potlako le ho futhumatsa;

(3) Ho hanyetsa mocheso o phahameng: Ho hanyetsa mocheso o phahameng, ho khona ho mamella mocheso o phahameng ho tloha 1200 ho ea ho 1650 ℃;

(4) Ho hanyetsa khoholeho ea mobu: Ho hanyetsa ka matla khoholehong ea sopho e entsoeng ka ho qhibilihisoa;

(5) Ho hanyetsa tšusumetso ea mochine: ho ba le tekanyo e itseng ea matla khahlanong le tšusumetso ea mochine (e kang ho kenya thepa e entsoeng ka ho qhibilihisoa)

(6) Ho hanyetsa oxidation: Graphite e na le tšekamelo ea ho oxidation ka mocheso o phahameng ka li-aerosols tsa oxidation, e leng se bakang tšebeliso e fokolang ea oxidation ka lebaka la phekolo ea thibelo ea oxidation;

7

8

(9) Tšusumetso ea moqoqo oa slag (slag remover): E na le khanyetso e ntle khahlanong le tšusumetso ea moqokelli oa slag (slag remover) ts'ebetsong.

Li-crucible tsa rona tsa Silicon carbide li sebelisoa lits'ebetsong tse fapaneng tsa indasteri, joalo ka tšepe, tlhahiso ea semiconductor, tlhahiso ea likhalase le indasteri ea lik'hemik'hale.Li-crucible tsa rona tsa Silicon carbide li na le molemo oa ho qhibiliha ha mocheso o phahameng le ho hanyetsa tlhaselo ea lik'hemik'hale.Li tsejoa ka mokhoa oa tsona o motle oa ho futhumatsa mocheso, ho hanyetsa mocheso o phahameng oa mocheso, le ho hanyetsa tlhaselo ea lik'hemik'hale.

Lintlha tse tloaelehileng tsa tlhahlobo ea parameter

Ho hanyetsa mocheso ≥ 1630 ℃ Ho hanyetsa mocheso ≥ 1635 ℃

Likahare tsa khabone ≥ 38% Likahare tsa carbon ≥ 41.46%

Ho bonahala ho porosity ≤ 35% Ho bonahala porosity ≤ 32%

Boima ba molumo ≥ 1.6g/cm3 Boima ba molumo ≥ 1.71g/cm3

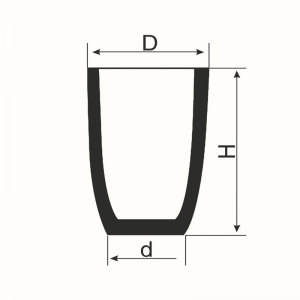

| Ntho | Khoutu | Bophahamo | Kantle Diameter | Phase bophara |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

1.Na u amohela tlhahiso e hlophisitsoeng ho latela litlhaloso tsa rona?

Ee, tlhahiso e ikhethileng e ipapisitse le litlhaloso tsa hau tse fumanehang ka ts'ebeletso ea rona ea OEM le ODM.Re romelle setšoantšo kapa mohopolo oa hau, 'me re tla u etsetsa setšoantšo.

2.Na nako ea ho pepa ke efe?

Nako ea ho fana ke matsatsi a 7 a ho sebetsa bakeng sa lihlahisoa tse tloaelehileng le matsatsi a 30 bakeng sa lihlahisoa tse hlophisitsoeng.

3.MoQ ke eng?

Ha ho na moeli ho bongata.Re ka fana ka tlhahiso e ntle ka ho fetisisa le tharollo ho latela boemo ba hau.

4.Ho sebetsana joang le ba nang le phoso?

Re hlahisitse lits'ebetso tse thata tsa taolo ea boleng, ka sekhahla se nang le phoso se ka tlase ho 2%.Haeba ho na le mathata leha e le afe ka sehlahisoa, re tla fana ka phetoho ea mahala.