Mofuta oa Graphite o Tloaelehileng

Likaroloana

Khampani ea rona e sebetsa ka ho khetheha ka lihlahisoa tsa carbon graphite: lihlopha tse supileng tse kholo:

1. Non ferrous tšepe smelting le sebetsa letoto la lihlooho tse

2. Diamond sesebelisoa sintering hlobo letoto la lihlooho tse

3. Mechanical Industry Series

4. Letoto la EDM

5. Letoto la kalafo ea sebōpi sa indasteri ea mocheso o phahameng oa mocheso

6. Electronic Semiconductor Industry Series

7. Letoto la masimo a theknoloji e phahameng

- Tlhahiso e nepahetseng

- Ts'ebetso e nepahetseng

- Lithekiso tse tobileng ho tsoa ho bahlahisi

- Likarolo tse kholo ka har'a stock

- Customized ho ea ka litšoantšo

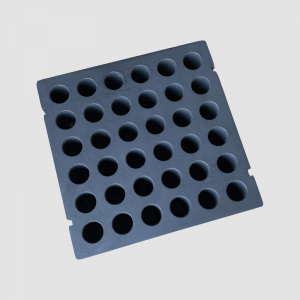

Lihlahisoa tse ka sehloohong tsa tlhahiso le ts'ebetso li kenyelletsa: litlhaloso tse fapaneng tsa li-graphite blocks, li-graphite discs, li-alloys tse thata tsa graphite tube, li-graphite Arks bakeng sa sintering ea phofo ea metallurgy, likepe tse chitja tsa graphite, likepe tse bōpehileng joaloka graphite, lipoleiti tsa sekepe le liforomo tsa graphite, li-crystallizers bakeng sa ho tsoela pele ho lahla litšepe tse se nang ferrous, li-stoppers, likotlolo tse ka tlase, metheo, liphaephe tse tšollang, liphaephe tse phallang, lik'hemik'hale tsa lik'hemik'hale, ho putlama ha graphite, lithupa tsa graphite, lipoleiti tsa graphite, graphite e sa sebetseng haholo. Khalase ea quartz e hlahisa likarolo tsa graphite tse kang mabili a mangata, li-rollers, mabota a bolokang, li-clamps tsa botlolo, joalo-joalo. libopi tsa ho hanyetsa, libono tsa induction, libono tse chesang, libopi tsa brazing, libopi tsa ion nitriding, le libopi tse timang li-vacuum bakeng sa libono tse kholo tse qhibilihisang sakha.Li-tubes tsa graphite sebōpi le lipoleiti tse thibelang kutu bakeng sa lik'hemik'hale.Indasteri ea chlorine alkali, indasteri ea electroplating le electrolysis, indasteri ea ho lahla poleiti ea graphite anode, li-graphite tse batang tsa tšepe bakeng sa tlhahiso ea aluminium ea hlobo, mehele ea graphite, li-rollers, likhoele, lipoleiti, lisebelisoa tsa daemane, hlobo ea graphite, hlobo ea geological drill sintering bakeng sa tlhahiso ea matla a macha. lisebelisoa tse kang li-cartridge tsa graphite bakeng sa lisebelisoa tsa betri ea carp, li-graphite saggers, joalo-joalo

Lihlahisoa tsohle ke 100% lifoto tsa 'mele, tse nang le thepa ea pele le boleng bo tiisitsoeng.Lipontšo tsohle, litekanyo tse qaqileng, lileibole tsa thepa, le litlhaloso tsa lihlahisoa li fanoe ka litaelo tse qaqileng.Haeba e fumaneha lishelefong, e bolela hore e teng.Haeba u na le lipotso, ka kopo ikopanye le litšebeletso tsa bareki hang-hang.

Lihlahisoa tsohle li nkuoa lifoto ke litsebi tsa litsebi ho netefatsa hore li lumellana le sehlahisoa sa sebele.Leha ho le joalo, ka lebaka la ho kheloha ha mabone, tharollo ea lisebelisoa tsa k'homphieutha, le kutloisiso ea botho ea mebala nakong ea ho thunngoa, ntho e amoheloang e ka 'na ea fapana le setšoantšo, e seng taba ea boleng.Ka kopo sheba ntho e amohetsoeng e le maemo.