CNC e etselitsoeng poleiti ea graphite

Likaroloana

1) Lisebelisoa tsa refractory: indastering ea ho qhibilihisa, lipoleiti tsa graphite li sebelisetsoa ho etsa li-crucible tsa graphite, e le lisebelisoa tse sireletsang li-ingots tsa tšepe, le litene tsa carbon tsa magnesia bakeng sa lesela la libōpi tse qhibilihisang.

2) Lisebelisoa tsa conductive: indastering ea motlakase, graphite e sebelisoa haholo joalo ka li-electrode, borashe, li-tubes tsa carbon, le liphahlo tsa li-tubes tsa thelevishene.

3) Apara lisebelisoa le mafura a manganga: Lisebelisoa tse ngata tsa mochini, lipoleiti tsa graphite li sebelisoa e le lisebelisoa tse sa sebetseng le tse tlotsang, tse ka thellang ka lebelo la 100m/s ka har'a mocheso oa -200 ho isa ho 2000 ℃ ntle le ts'ebeliso e nyane kapa e nyane. oli e tlotsang.

4) Lisebelisoa tsa ho tiisa: Sebelisa graphite e feto-fetohang e le li-gaskets tsa piston, mehele ea ho tiisa, joalo-joalo bakeng sa lipompo tsa centrifugal, li-turbine tsa metsi, li-turbine tsa mouoane, le lisebelisoa tse tsamaisang mecha ea litaba e senyang.

5) Thepa e sa khoneng ho bola: E sebelisa lipoleiti tsa graphite e le likepe, liphaephe le lisebelisoa, e khona ho mamella ho bola ha likhase tse sa tšoaneng tse senyang le maro 'me e sebelisoa haholo mafapheng a kang petroleum, lik'hemik'hale le hydrometallurgy.

6) Tšireletso ea mocheso, ho hanyetsa mocheso o phahameng, le lisebelisoa tsa ts'ireletso ea mahlaseli a kotsi: Lipoleiti tsa graphite li ka sebelisoa e le li-moderator tsa nyutrone ho li-reactor tsa nyutlelie, hammoho le li-nozzles, li-cone tsa nko, likarolo tsa lisebelisoa tsa sefofane, lisebelisoa tsa ho futhumatsa mocheso, lisebelisoa tsa tšireletso ea mahlaseli, joalo-joalo.

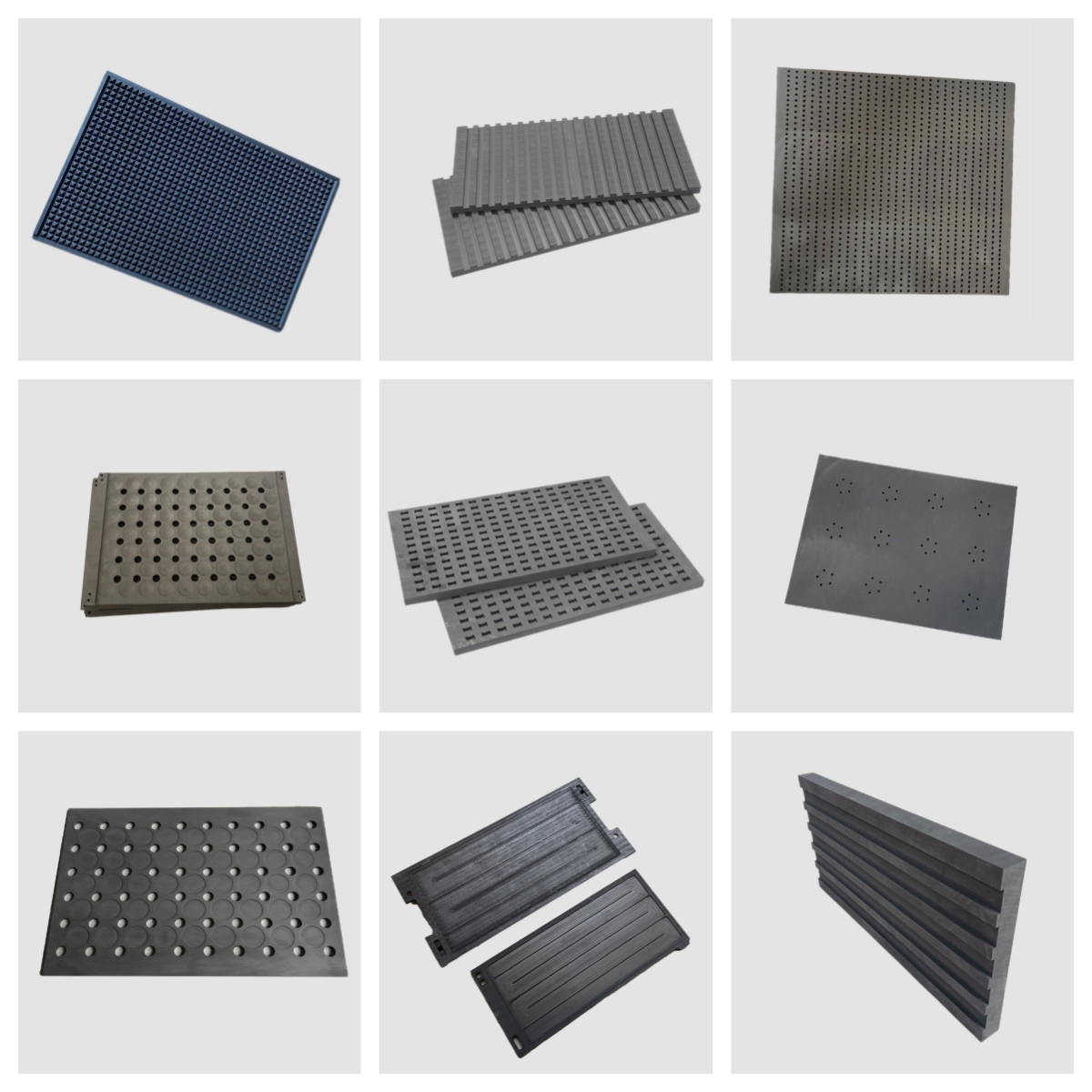

1. Isotropy e ntle, litšobotsi tse ikemetseng ka boholo, sebopeho, le tataiso ea lisampole;

2. Sebopeho se ts'oanang, ho teteana, le bokhoni bo matla ba antioxidant;

3. Ho itlotsa ka mokhoa o babatsehang;

4. Ho hanyetsa hantle lik'hemik'hale;

5. High conductivity ea mocheso le ts'ebetso ea botsitso ba mocheso;

6. Matla a lekaneng a mochine le ho hanyetsa tšusumetso;

7. Ho bonolo ho mochini mme e ka sebetsoa ka libopeho tse fapaneng tsa geometri ho latela litlhoko.

Ha u sebelisa pompo e ncha, ela hloko tataiso ea enjene 'me u qobe ho e hokahanya ho khutlela morao.Ho potoloha ha pompo nako e telele ho tla senya li-blades.

Lerōle le feteletseng tikolohong ea ts'ebetso ea pompo le ho sefa moea o sa lekaneng ho ka potlakisa ho roala ha lehare le ho fokotsa nako ea bophelo ea lehare.

Libaka tse mongobo li ka baka kutu holim'a li-blades le marako a rotor slot.Ha u qala pompo ea moea, likarolo tsa lehare ha lia lokela ho lahleloa ka ntle, kaha khatello e sa lekaneng e ka senya mahare.Maemong a joalo, li-blades li lokela ho hlahlojoa le ho hloekisoa pele.

Ho chencha khafetsa ha u ntse u sebelisa pompo ho eketsa palo ea litšusumetso nakong ea ejection ea lehare, ho fokotsa nako ea bophelo ea mahare.

Boleng bo bobe ba lehare bo ka fella ka ho fokotseha ha ts'ebetso ea pompo kapa ho senya marako a li-cylinder, kahoo e lokela ho qojoa.

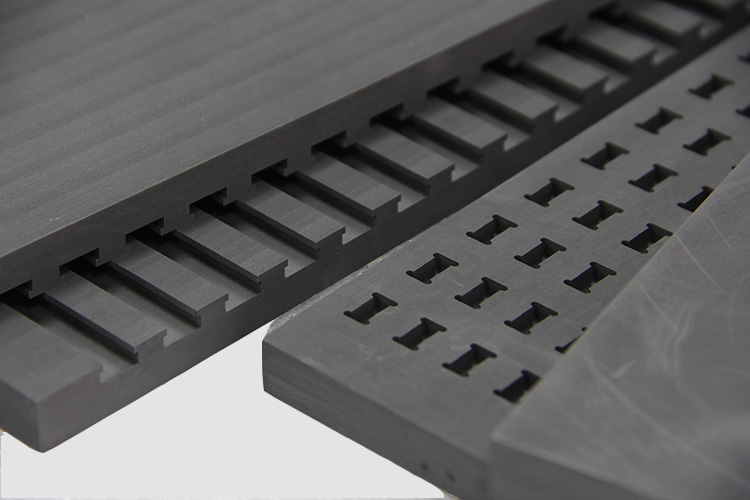

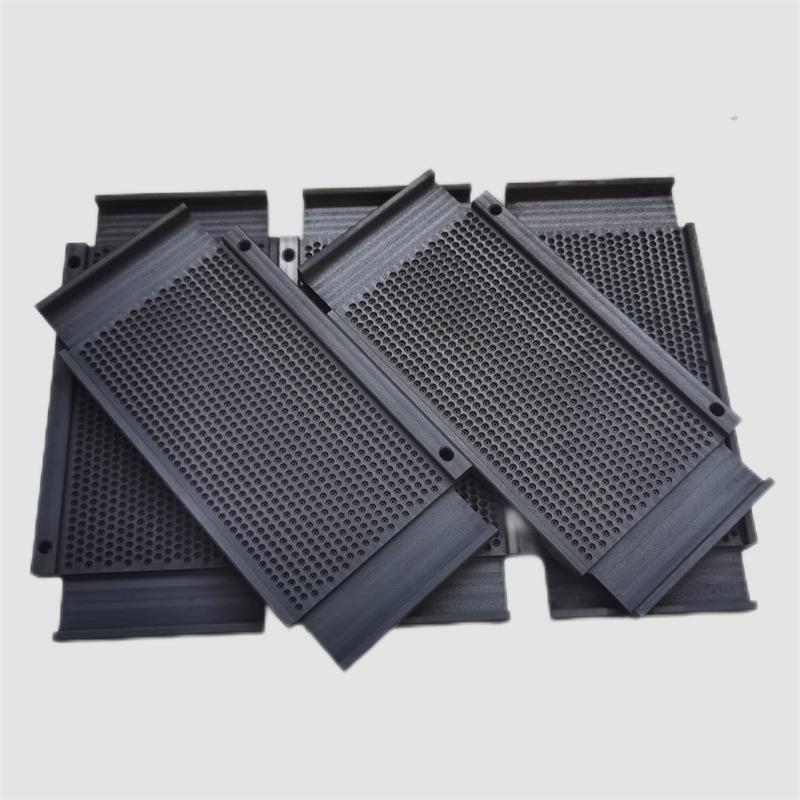

1. Bokhoni bo matla ba ho sebetsa, bo khonang ho fana ka litlhaloso tse fapaneng le lipoleiti tsa graphite tse spliced.

2. Re ka fana ka lihlahisoa tsa graphite bakeng sa ho bōptjoa ha extrusion, ho thothomela ho thothomela, ho bōptjoa, le ho hatisa isostatic ha ho hlokahala.

3. Ho ea ka litlhoko tse fapaneng tsa theknoloji, lihlahisoa tsa graphite tse kang lipoleiti tsa graphite li ka ba tlas'a phekolo ea ho hanyetsa oxidation, phekolo ea ho se khonehe, le phekolo ea ho matlafatsa ho ntlafatsa ts'ebetso ea bona le bophelo ba tšebeletso.