Kenyelletso

Ho khetha se matla ka nepo ho bohlokoa bakeng sa tšepe e sebetsang le ho lahla lits'ebetso tsa ho lahla. Hore na oa sebetsa leLi-curbites tsa silicon carbime or graphing Graphie, ho utloisisae sebelisoa, mocheso oa mocheso, leLINTHO TSE HLAHANGho matlafatsa tlhahiso le ts'ebetso. Sehloohong sena, re tla koahela tsohle tseo u lokelang ho li tseba, ho tlohaboholo ba graphite to ho benya ha silicon ho tlamo, ha a araba lipotso tse kangHo sebelisoa eng ho qhibiliha tšepe?MmeSilevera e leka joang?

Kemiso

1. Li-carbides tsa siling le li-gradite tse khabisitsoeng ke life?

- Li-curbites tsa silicon carbime: E entsoe ka seboko sa boleng bo holimo le thupa ea graphite e phahameng, lintho tsena li tsebahala ka lithemparetjha tse phahameng, oxida le matloana a futhumatsang.

- Graphing Graphie: E entsoe ka graphite e hloekileng, lits'oants'o tsena li hlahisa botsitso ba mocheso bo phahameng 'me ba loketse tšepe ka lintlha tse ngata tse qhibilihang.

2. Likarolo tsa Bohlokoa le Likopo

- Mocheso oa mocheso:

Mofuta oa ho qhekella Mocheso oa mocheso (° C) Silicon carbide Ho fihlela ka 1650 ° C Graphite Ho fihla ho 3000 ° C - Likopo: Mefuta eo e sa lokelang ho qhibiliha bakeng sa ho qhibiliha le ho hloekisa tšepe e seng litšila joalo ka koporo, silevera le khauta. Hangata e sebelisoa ka mekhoa ea mabenyane, e etsoang le lits'ebetso tse tsoelang pele tsa lelekotso.

- Ho Tšoara:

- Li-curbibles tsa silicon carbistive ke sesupo sa ho roala mafura ebile se etselitsoe ho futhumala khafetsa.

- Lits'oants'o tsa Graphie li tsitsitse 'me li ka khona ho sebetsana le libaka tse tharo.

3. Boholo ba kharaphite le ho tsamaisana le tšepe

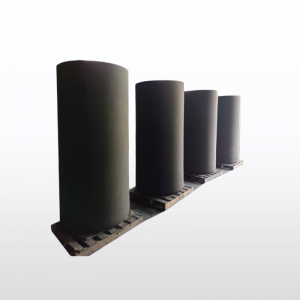

- Boholo:

Lits'oants'o tsa litšoantšo li fumaneha ka boholo bo lekantsoeng ka boholo ba ho lumellana le likopo tse ngata tsa indasteri.Boholo Bokhoni Nyane 1-5 kg Metsi a mahareng 6-20 kg Kholo 21 kg le kaholimo - Khokahano ea tšepe:

Mofuta oa tšepe Ntlha ea ho qhibiliha (° C) E khothalelitsoe ho ts'oaroa Koporo ~ 1085 Mofuta oa carlizon kapa graphite Silifera ~ 961 Mofuta oa carlizon kapa graphite Khauta ~ 1064 Graphite

4. Silizon carbide le profictite e sa sebetseng

- Li-curbites tsa silicon carbime: E loketse tšepe e hlokang potoloho e futhumatsang e futhumatsang, e kang hoTs'ebetso e tsoelang pele ea ho leleka.

- Graphing Graphie: O ratoa haholo bakeng sa tšepe e phahameng le e le likarolo tsali-turnaces tsa ladle, Manipulator ea Shroud, lemaqhubu a tiushka lebaka la boitšoaro ba bona bo botle.

5. Tlhokomelo le Malebela a Tlhokomelo

Ho eketsa theko ea theko le katleho:

- Qoba liphetoho tsa mocheso ka tšohanyetso: Thibela mapetso a bakoang ke ho makala ha a futhumatsang.

- Ho Hloekisa Kamehla: Tlosa slag le masala ka mor'a ts'ebeliso e 'ngoe le e' ngoe.

- Ho boloka ka nepo: Boloka tikoloho e omileng, e se nang mofuthu ho qoba ho ts'oaroa ha lintho tse bonahalang.

Li-Faq tse tloaelehileng tsa bareki ba litsebi

- Q: Ho sebelisoa eng ho qhibiliha likepe tse kang koporo le silevera?

A: Li-Chebides tsa silika le Graphin le Graphie li sebelisoa hangata ka lebaka la lintlha tsa tsona tse qhibilihang le botsitso bo boholo ba futhumatsang. - Q: Temple ea koporo le Graphie ke eng?

A: Pipper e qhibiliha ho batho ba ka bang 1085 °, ha lits'oants'o tsa li-granite li khona ho mamella likhopolo ho fihlela 3000 c. - Q: Ke efe e sa tšoaneleheng e loketseng cashlil ea indasteri?

A: Lits'oants'o tsa Graphie li khethoa bakeng sa tšepe ea mocheso o phahameng, ha litšitiso tsa ho kuta likepe tsa silise li loketse lipotoloho tse futhumatsang tikolohong ea tlhahiso.

Hobaneng o re khetha?

Re fana ka litharollo tse etellang pele tsa indasteringsilicon carbideMmegraphing Graphie.

| Melemo ea rona | Lebaka Leo ho Le Hlollang |

|---|---|

| Boholo bo fapaneng | Ho tloha hanyane ka hanyane ho sebelisoa indarista. |

| Lisebelisoa tsa Premium | Mofuta oa mofuta o phahameng oa siramium ea boleng bo holimo le kharafi e hloekileng e tiisa ho tšepahala nako e telele. |

| Tharollo ea moetlo | Meralo ea Lipehelo tsaladle shrouds, Li-nozzles tse kenellangle lisebelisoa tse ling tse lelekelang. |

| Ts'ehetso ea Setsebi | Mashome a lilemo a mang aHo etsa tšepeMmeMetal Castings Castings. |

U se u loketse ho ntlafatsa ts'ebetso ea hau ea ho lahla? Ikhethileng Rona Kajeno hore re se ke tsa bakoa haholo tse etselitsoeng ho fihlela litlhoko tsa khoebo tsa hau!

Nako ea poso: nov-19-2024