Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

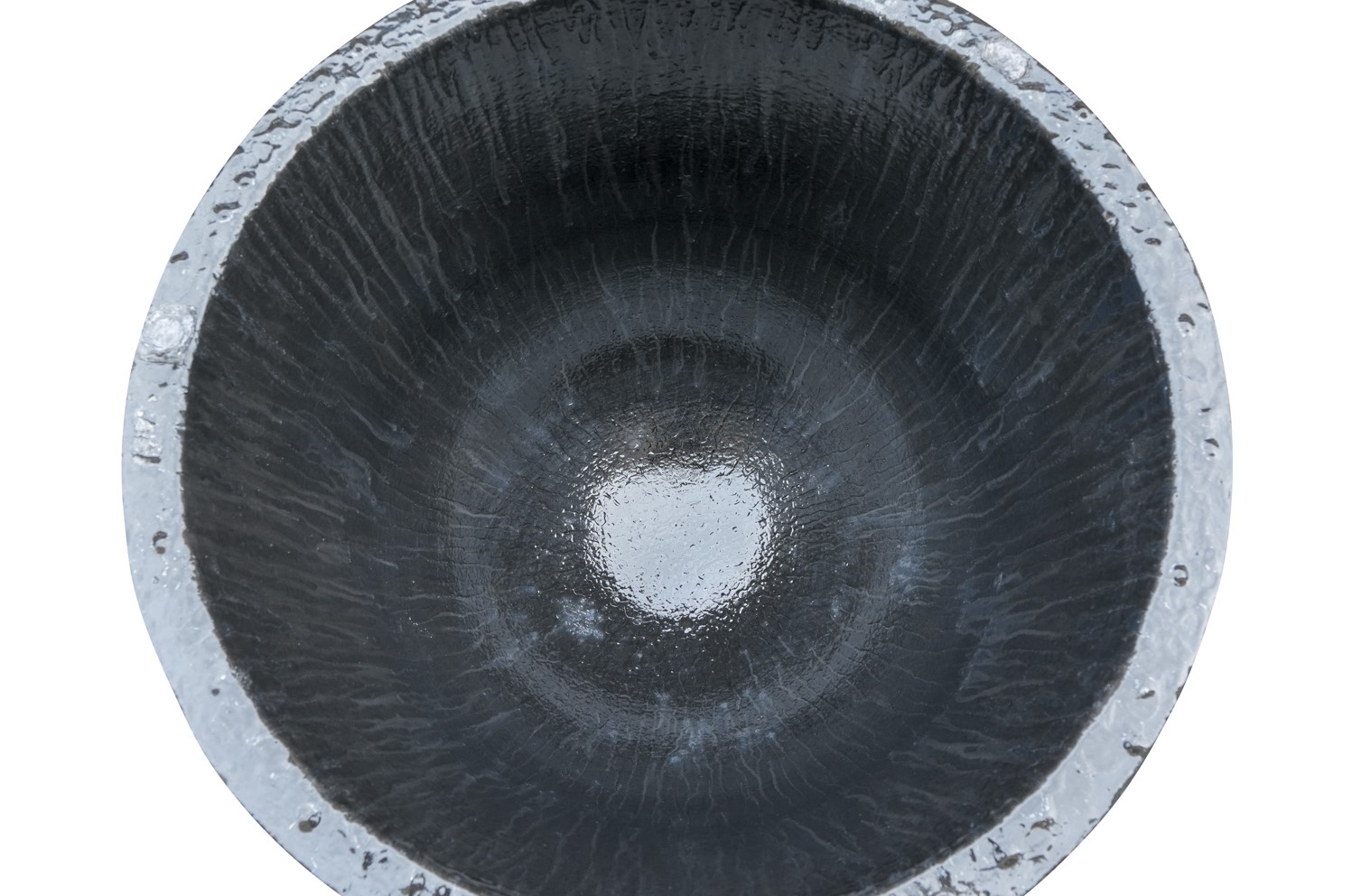

Qhibiliha Metal Crucible Foromo Cylinder Zylinder

LIEKETSENG LIHLAHISO

Ho qhibiliha ka potlako

Lisebelisoa tsa graphite tse phahameng tsa mocheso li ntlafatsa ts'ebetso ea mocheso ka 30%, e fokotsa haholo nako ea ho qhibiliha.

Phehisano e phahameng ea Thermal Shock

Theknoloji e kopantsoeng le resin e mamella ho futhumala ka potlako le ho pholile, ho lumella ho tjhaja ka ho toba ntle le ho phunyeha.

Tšireletseho e Ikhethang

Matla a phahameng a mochine a hanela tšusumetso ea 'mele le khoholeho ea lik'hemik'hale bakeng sa bophelo bo bolelele ba tšebeletso.

LIEKETSENG MOKHOPO

| Graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Boima ba bongata / g·cm⁻³ | 2.20 |

| Ho bonahala ho porosity / % | 10.8 |

| Matla a ho pshatla/MPa (25℃) | 28.4 |

| Modulus of rupture/ MPa (25℃) | 9.5 |

| Mocheso o hanyetsanang le mollo/ ℃ | >1680 |

| Mocheso oa ho tsikitlana / Mehla | 100 |

| No | Mohlala | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

TS'EPISO TS'OANE

1. Tlhahiso e nepahetseng

graphite e phahameng-hloeka + premium silicon carbide + moemeli ea tlamellang.

.

2.Isostatic Pressing

Boima ba ho fihla ho 2.2g/cm³ | Mamello ea botenya ba lebota ± 0.3m

.

3.Mocheso o Phahameng oa Sintering

SiC particle recrystallization e etsa sebopeho sa marang-rang sa 3D

.

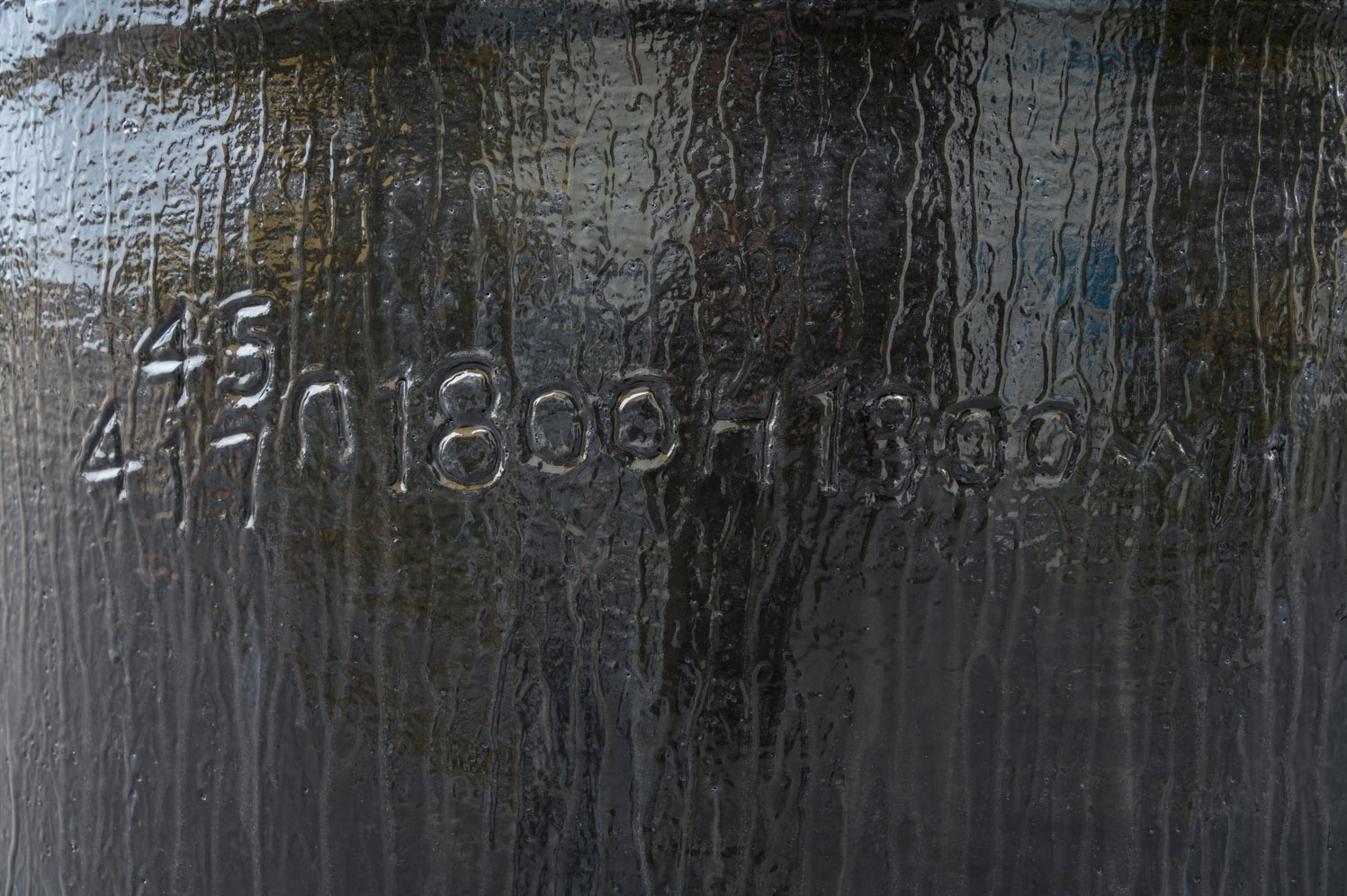

5.Tlhahlobo e Matla ea Boleng

Khoutu e ikhethileng ea ho lata bakeng sa traceability e felletseng ea bophelo

.

4. Ntlafatso ea Sefahleho

Anti-oxidation coating → 3 × e ntlafetseng ea ho hanyetsa kutu

.

6.Polokeho Packaging

Lera le monyang ho tsukutloa + Mothibelo oa mongobo + Mokotla o matlafalitsoeng

.

SEBELISA SEHLAHISO

E loketse litšepe tse ngata tse se nang ferrous

Qhibiliha Aluminium

Qhibiliha Koporo

Qhibiliha Khauta

KE HOBANE'NG LE RE KHETHA

FAQS

Q1: Na The Crucible Cover e ka fokotsa litšenyehelo tsa matla?

A: Ruri! E fokotsa tahlehelo ea mocheso, e fokotsa tšebeliso ea matla ka 30%.

Q2: Ke libopi life tse lumellanang?

K: E na le lintho tse ngata tse ngata—e loketse bakeng sa ho induction, khase le libōpi tsa motlakase.

Q3: Na graphite silicon carbide e bolokehile bakeng sa mocheso o phahameng?

A: Ho joalo. Ho tsitsa ha eona ka mocheso le lik'hemik'hale ho etsa hore e be e phethahetseng bakeng sa maemo a feteletseng.

Q4: Ke litekanyo life tse teng bakeng sa li-crucible tsa hau tsa tšepe tse qhibilihang?

A: Re fana ka mefuta e fapaneng ea boholo, e nang le litlhaloso tse kenyeletsang bophahamo, bophara ba ka ntle, le bophara bo ka tlase bo etselitsoeng ho finyella litlhoko tsa hau.

Q5: Nka etsa bonnete ba boleng ba li-crucible tsa hau joang?

A: Ts'ebetso ea rona ea tlhahiso e latela litekanyetso tse thata tsa boleng, e netefatsa ts'ebetso e ikhethang le ts'epahalo.

Q6: A na nka kopa moralo o tloaelehileng oa crucible ea ka?

A: Ruri! Re amohela lipotso bakeng sa meralo e hlophisitsoeng le litlhoko tse khethehileng tsa ts'ebetso.

Thuto-pale #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Thuto-pale #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Bopaki

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe