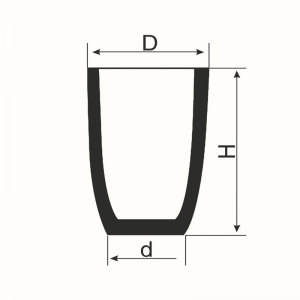

Boitsebiso:

Tsa ronaCylindrical Cruciblee entsoe ka silicon carbide graphite e hatelitsoeng ka isostatically, e leng thepa e fanang ka khanyetso e phahameng ea mocheso le mocheso o motle haholo, e leng se etsang hore e be sesebelisoa sa bohlokoa bakeng sa lisebelisoa tsa ho qhibilihisa indasteri.

- Silicon Carbide (SiC): Silicon carbide e tsebahala ka ho thatafala ha eona ho feteletseng le ho hanyetsa ka mokhoa o babatsehang ho apara le ho senya. E ka mamella liphetoho tsa lik'hemik'hale tse phahameng tsa mocheso, e fana ka botsitso bo phahameng esita le tlas'a khatello ea mocheso, e leng ho fokotsang kotsi ea ho senya nakong ea liphetoho tsa tšohanyetso tsa mocheso.

- Natural Graphite: Graphite ea tlhaho e fana ka ts'ebetso e ikhethang ea mocheso, e netefatsa phano ea mocheso e potlakileng le e ts'oanang ho pholletsa le crucible. Ho fapana le li-graphite crucibles tsa letsopa tse tloaelehileng, cylindrical crucible ea rona e sebelisa graphite ea tlhaho e hloekileng haholo, e ntlafatsang katleho ea mocheso oa mocheso le ho fokotsa tšebeliso ea matla.

- Theknoloji ea Isostatic Pressing: The crucible e thehoa ho sebelisoa khatiso e tsoetseng pele ea isostatic, ho netefatsa hore ho na le boima bo tšoanang bo se nang bofokoli ba ka hare kapa ba ka ntle. Theknoloji ena e ntlafatsa matla le ho hanyetsa ho phunyeha ha crucible, ho atolosa ho tšoarella ha eona libakeng tse phahameng tsa mocheso.

Tshebetso:

- Superior Thermal Conductivity: Cylindrical Crucible e entsoe ka thepa e phahameng ea mocheso oa mocheso o lumellang ho ajoa ka potlako esita le mocheso. Sena se matlafatsa ts'ebetso ea ts'ebetso ea ho qhibilihisa ha se ntse se fokotsa tšebeliso ea matla. Ha ho bapisoa le li-crucibles tse tloaelehileng, conductivity ea mocheso e ntlafatsoa ka 15% -20%, e lebisang ho poloko e kholo ea mafura le potoloho ea tlhahiso e potlakileng.

- Khahlano e Ntle ea Corrosion: Lithako tsa rona tsa silicon carbide graphite crucibles li hanyetsana haholo le litlamorao tse senyang tsa tšepe le lik'hemik'hale tse qhibilihisitsoeng, tse netefatsang botsitso le bophelo bo bolelele ba crucible nakong ea ts'ebeliso ea nako e telele. Sena se etsa hore e be tse loketseng bakeng sa ho qhibilihisa aluminium, koporo, le lisebelisoa tse fapaneng tsa tšepe, ho fokotsa tlhokomelo le makhetlo a mangata.

- Bophelo bo Atolositsoeng ba Tšebeletso: Ka sebopeho sa eona se phahameng le se matla haholo, nako ea bophelo ea cylindrical crucible ea rona ke 2 ho linako tse 5 ho feta li-crucible tsa letsopa tsa graphite tse tloaelehileng. Khanyetso e phahameng ea ho senya le ho apara e atolosa bophelo ba ts'ebetso, ho fokotsa nako ea ho theoha le litšenyehelo tsa ho fetola.

- High Oxidation Resistance: Sebopeho se entsoeng ka mokhoa o khethehileng se thibela oxidation ea graphite, se fokotsa ho senyeha ha mocheso o phahameng le ho lelefatsa bophelo ba crucible.

- Matla a Phahameng a Mechini: Ka lebaka la ts'ebetso ea ho hatella ea isostatic, crucible e ithorisa ka matla a ikhethang a mochini, e boloka sebopeho sa eona le ho tšoarella maemong a mocheso o phahameng. Sena se etsa hore e be se loketseng bakeng sa mekhoa ea ho qhibiliha e hlokang khatello e phahameng le botsitso ba mechine.

Melemo ea Sehlahisoa:

- Melemo ea Lintho: Tšebeliso ea graphite ea tlhaho le silicon carbide e tiisa hore ho na le conductivity e phahameng ea mocheso le ho hanyetsa kutu, ho fana ka ts'ebetso e tšoarellang libakeng tse thata, tse phahameng tsa mocheso.

- Sebopeho sa High-Density: Theknoloji ea ho hatella ea Isostatic e tlosa likheo le mapetsong a ka hare, e ntlafatsa haholo ho tšoarella le matla a crucible nakong ea tšebeliso e telele.

- Botsitso bo Phahameng ba Mocheso: E khona ho mamella mocheso ho fihla ho 1700 ° C, crucible ena e loketse mekhoa e fapaneng ea ho qhibilihisa le ho lahla e kenyelletsang tšepe le li-alloys.

- Matla a Matla: Thepa ea eona e phahameng ea phetisetso ea mocheso e fokotsa tšebeliso ea mafura, athe thepa e baballang tikoloho e fokotsa tšilafalo le litšila.

Ho khetha ts'ebetso ea rona e phahameng ea Cylindrical Crucible e ke ke ea ntlafatsa ts'ebetso ea hau ea ho qhibilihisa feela empa hape ho fokotsa tšebeliso ea matla, ho lelefatsa nako ea bophelo ba lisebelisoa, le litšenyehelo tse tlase tsa tlhokomelo, qetellong ho ntlafatsa katleho ea tlhahiso.

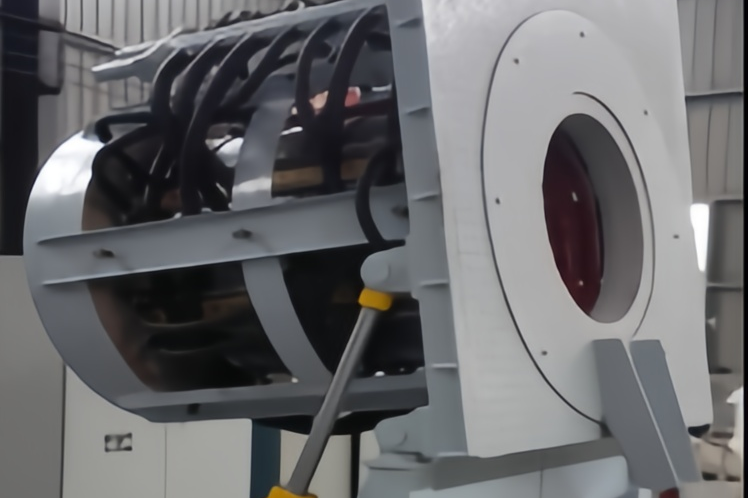

Liindastering tsa sejoale-joale tsa ho sebetsa ka tšepe le ho li sebelisa hape, ho futhumatsa ka induction e se e le mokhoa o ratoang bakeng sa ts'ebetso e nepahetseng le e nepahetseng ea ho qhibiliha. Khetho ea crucible e phetha karolo ea bohlokoa ho netefatsa hore lits'ebetso tsena li tsamaea hantle, haholo-holo libonong tsa induction. Re ntlafalitseLi-Crucibles tsa ho futhumatsa ka Inductionho sebelisa theknoloji ea khatiso ea isostatic ho fana ka ts'ebetso e ke keng ea lekanngoa lits'ebetsong tsena tse hlokang.

Ho fapana le li-crucibles tse tloaelehileng, tse ka 'nang tsa thatafalloa ke matla a khoheli ka har'a libopi tsa induction, li-crucibles tsa rona li etselitsoe ho hlahisa mocheso ka ho kenngoa ha makenete. Mokhoa ona o mocha ha o ntlafatse matla a matla feela empa o boetse o lelefatsa nako ea bophelo ea crucible, e leng se etsang hore e be khetho e nepahetseng bakeng sa liindasteri tse kang ho tsosolosa aluminium le ho etsa tšepe.

Thepa ea makenete ea li-crucibles tsena e bohlokoa ka ho khetheha ho basebelisi ba libono tsa induction, moo bokhoni ba ho tsamaisa mocheso ka ho kenya letsoho ho ka eketsang ts'ebetso ea kakaretso ea ts'ebetso. Sena ha se boloke nako feela empa se boetse se fokotsa litšenyehelo tsa matla, se etsa hore e be tharollo e baballang likhoebo.

Lisebelisoa tsa li-Crucible tsa ho futhumatsa ka Induction

- Indasteri ea ho Hlakola Aluminium:

- Ka indasteri ea aluminium e sebelisoang hape, ho hanyetsa kutu ho bohlokoa ka lebaka la maemo a thata a amehang ts'ebetsong. Li-crucible tsa rona li etselitsoe ka ho khetheha ho sebetsana le maemo ana, li fana ka nako ea bophelo e fetang crucibles ea Europe ka ho feta 20%.

- The high conductivity thermal conductivity netefatsa nako ea ho qhibiliha ka potlako, e leng se matlafatsang tlhahiso le ho fokotsa tšebeliso ea matla.

- Li-Induction Furnaces:

- Hangata li-crucibles tsa setso ha li na matla a khoheli, tse ka fellang ka ho se sebetse hantle ha li sebelisoa libōping tsa induction. Li-crucible tsa rona tsa ho futhumatsa li entsoe ka matla a ho futhumatsa a makenete, ho bolelang hore crucible ka boeona e hlahisa mocheso, e ntlafatsa ts'ebetso ea ts'ebetso ka kakaretso le ho fokotsa litšenyehelo tsa matla.

- Ka nako e fetang selemo, li-crucibles tsena li feta tsa balekane ba tsona haholo, li fokotsa nako ea ho theoha le litšenyehelo tsa ho nchafatsa.

- Lisebelisoa tse ling tsa ho qhibilihisa tšepe:

- Ebang ke ts'ebetso ea koporo, zinki, kapa silevera, li-crucible tsa rona li fana ka ts'ebetso e tšepahalang, e netefatsang liphetho tse tsitsitseng ho pholletsa le liindasteri tse fapaneng.

Malebela a Tlhokomelo le Tšebeliso ea Li-Crucible tsa ho futhumatsa ka Induction

Ho eketsa nako ea bophelo le katleho ea Induction Heating Crucible ea hau, ho bohlokoa ho latela mekhoa e nepahetseng ea ts'ebeliso le tlhokomelo:

- Preheating: Butle-butle futhumatsa crucible ho mocheso o lakatsehang ho qoba mocheso oa mocheso.

- Ho hloekisa: Hloekisa crucible khafetsa ho tlosa mesaletsa e ka amang ts'ebetso le ho khutsufatsa nako ea bophelo.

- Polokelo: Boloka likotoana sebakeng se omeletseng, se phodileng ho thibela ho pepesehela mongobo kapa lintho tse senyang tse ka senyang thepa ha nako e ntse e ea.

Mekhoa ena e tla thusa ho netefatsa hore crucible ea hau e sebetsa ka katleho e phahameng ka nako e telele, ho fokotsa makhetlo a mangata a ho nkela sebaka le tlhokomelo.

Phatlalatso ea Sehlahisoa

Re motlotlo ho fana ka li-Induction Heating Crucibles tse etselitsoeng ho tšoarella le ho sebetsa hantle. Li-crucibles tsa rona li na le theknoloji ea ho hatella ea isostatic, e netefatsang ho ts'oana le matla, e leng se etsang hore e se ke ea hlola e e-ba le ts'oaetso ea mocheso le khatello ea mochine. Ka bokhoni ba ho hlahisa mocheso ka ho kenngoa ha makenete, li-crucible tsa rona li etselitsoe ka ho khetheha bakeng sa lisebelisoa tsa sebōpi sa induction, moo ho nepahala le ho sebetsa hantle ha matla ho leng bohlokoa.

Likhetho tsa ho Itloaetsa: Rea utloisisa hore indasteri e 'ngoe le e' ngoe e na le litlhoko tse ikhethang. Ke ka lebaka leo re fanang ka li-crucibles tse ikhethileng ka botlalo, tse etselitsoeng ho fihlela litlhoko tsa hau tsa ts'ebetso. Hore na o hloka sebopeho se fapaneng, boholo, kapa sebopeho, sehlopha sa rona se ikemiselitse ho sebetsa le uena ho theha tharollo e phethahetseng.

Tšehetso ea Theknoloji: Sehlopha sa rona se inehetseng se fana ka ts'ehetso e felletseng ea tekheniki ho u thusa ho fumana molemo o moholo ho li-crucibles tsa hau. Ho tloha ts'ebetsong ea pele ho ea ho keletso e tsoelang pele ea tlhokomelo, re mona ho netefatsa hore lits'ebetso tsa hau li tsamaea hantle le ka katleho.

Bitsa Ketso

Haeba u batla ho ntlafatsa katleho ea lits'ebetso tsa hau tsa ho futhumatsa ka induction, rona Induction Heating Crucibles ke tharollo e phethahetseng. Ka theknoloji ea ho hatella ea isostatic, lisebelisoa tse phahameng tsa ho futhumatsa tsa makenete, le nako e telele ea bophelo, li-crucibles tsena li fana ka ts'epo le ts'ebetso eo khoebo ea hau e e hlokang hore e lule e le pele 'marakeng oa tlholisano.

Ikopanye le rona kajeno ho ithuta haholoanyane ka litharollo tsa rona tsa crucible le kamoo li ka ntlafatsang lits'ebetso tsa hau tsa tlhahiso.