Lorem ipsum dolor sit amet consectetur adipiscing elit.

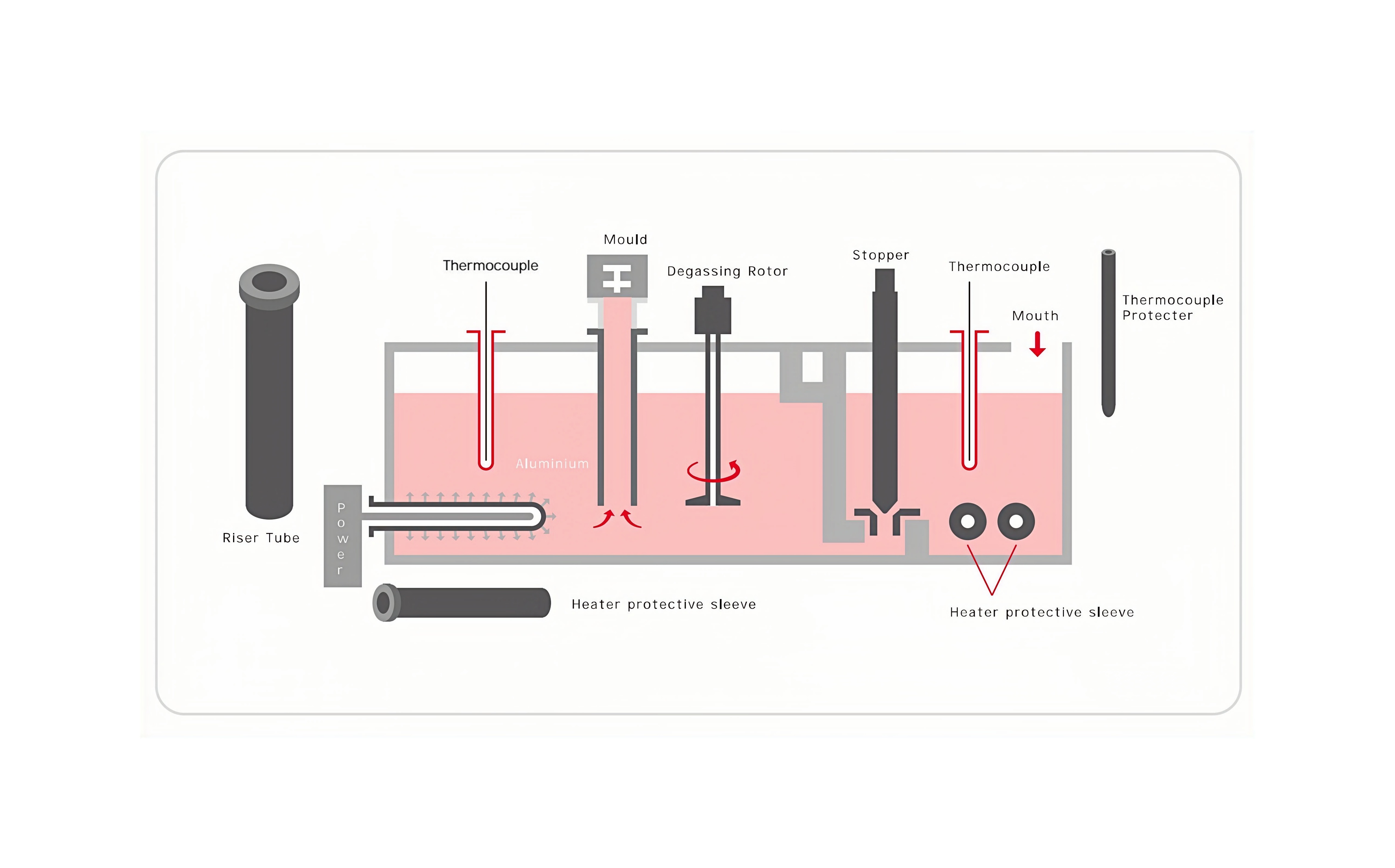

Silicon Nitride Degassing Rotor ka Mochini oa Degassing bakeng sa Aluminium Foundry

Boitsebiso bo Matla a Phahameng

High Wear Resistance

High Corrosion Resistance

Likarolo tsa mantlha

The silicon nitride degassing rotor, e nang le silicon nitride e le lisebelisoa tsa eona tsa mantlha, e kopanya moralo oa lebelo le phahameng haholo le taolo e nepahetseng ea sebopeho, e fihlelang katleho ea ts'ebetso ea ts'ebetso ea aluminium. Likarolo tsa eona tsa mantlha ke tse latelang:

I. Melemo ea Sesebelisuoa: Ho hanyetsa Mocheso, Ho hanyetsa ho Roala, 'me ha ho Tšoaetso.

- Bophahamo ba Tlhaho ho Feta Graphite: Rotor le impeller li entsoe ka silicon nitride. Ts'ebetso ea eona e nepahetseng le matla a eona a feta hole a graphite, e ts'ehetsang ho potoloha ka lebelo le holimo (ho fihla ho 8,000 rpm) le ho lelefatsa bophelo ba ts'ebeletso haholo.

- High - Temperature Oxidation Resistance: Ho batla ho se na oxidation libakeng tse phahameng tsa mocheso, ho qoba ka ho feletseng bothata ba "ho silafatsa aluminium e qhibilihisitsoeng" le ho netefatsa bohloeki ba sehlahisoa.

- Ho se sebetse ha Lik'hemik'hale: Ha e sebetsane le aluminium e qhibilihisitsoeng, e boloka ka mokhoa o tsitsitseng phello e nepahetseng ea ho senya nako e telele. Ha ho na lebaka la ho tšoenyeha ka ho senyeha ha thepa ho amang ts'ebetso.

II. Ho nepahala ha Sebopeho: Phahameng e Tsitsitseng - Ts'ebetso ea Lebelo, Sebaka sa Molten se Sephara

- Ultra - High Concentricity: The concentricity ea rotor e laoloa ka thata ka hare ho 0.2 mm (moo 1 "silika" = 0.01 mm). Nakong ea ho potoloha ka lebelo le phahameng, ho thothomela ho nyane haholo, ho felisa ho fetoha ha metsi ho bakoang ke ho lekana.

- Sistimi ea Khokahano e nepahetseng: Hlooho ea rotor le shaft e kopanyang li entsoe ka tšepe e sa hloekang, e nang le ts'ebetso e nepahetseng e fihlang boemong ba 0.01 - mm. Ho kopantsoe le kopano e nepahetseng haholo, "ho khanna ka lebelo le holimo" hoa fihlelleha, ho fokotsa ho feto-fetoha ha bokaholimo ba aluminium e qhibilihisitsoeng le ho netefatsa botsitso ba tlhahiso.

III. Lintlafatso tsa Ts'ebetso: Sebetsa, Botšepehi, le Phokotso ea Litšenyehelo

- Boima bo Phahameng + Matla a Phahameng: Thepa ena e 'meli e netefatsa ts'epahalo ea sebopeho mme ha ho kotsi ea deformation nakong ea ts'ebetso ea ultra - high - speed, e etsa hore e ikamahanye le maemo a feteletseng a ho sebetsa.

- Melemo e Ikhethileng e Bapisang: Ha e bapisoa le li-rotor tsa graphite, e hloka tataiso e felletseng bophelong ba ts'ebeletso, ho hanyetsa tšilafalo, le ho ikamahanya le maemo ka lebelo le phahameng. E fokotsa khafetsa ea ts'ebetso ea ho koala 'me ka tsela e sa tobang e ntlafatsa katleho ea tlhahiso.

Litlhaloso tsa Tekheniki

| Likaroloana | Melemo |

|---|---|

| Lintho tse bonahalang | graphite e phahameng haholo |

| Mocheso o Moholo oa ho sebetsa | Ho fihlela ho 1600°C |

| Khanyetso ea Corrosion | E ntle haholo, e boloka botšepehi ba aluminium e qhibilihisitsoeng |

| Bophelo ba Tšebeletso | E tšoarella nako e telele, e loketse ho sebelisoa khafetsa |

| Katleho ea Phallo ea Khase | E phahameng, ho netefatsa ts'ebetso e ts'oanang ea tlhoekiso |

Mokhoa oa ho khetha "Degassing Impeller"?

Mofuta oa F Rotor Φ250×33

Ka lebaka la boqapi bo khethehileng ba li-impeller grooves le meno a kantle a ka ntle, Mofuta oa F o etsa lipululana tse nyane. Boholo ba eona bo boholo bo ntlafatsa ho hasana ka aluminium e qhibilihisitsoeng, ha sehlopa se tšesaane se fokotsa ho feto-fetoha ha sebaka sa ho qhibiliha.

Kopo: E loketse li-ingot tse kholo tse bataletseng le melapo e chitja e qhibilihisang (habeli - rotor kapa triple - rotor degassing systems).

Mofuta oa B Rotor Φ200×30

Sebopeho sa impeller sa Mofuta oa B se hlahisa khatello e lekaneng ea ho etsa li-bubble tse nyenyane, tse ts'oanang ha li ntse li fokotsa mocheso oa mocheso.

Kopo: E loketse bakeng sa melapo e tsoelang pele ea ho lahla le ho qhibidiha (sistimi e le 'ngoe ea rotor degassing).

Mofuta oa D Rotor Φ200×60

Mofuta oa D o na le moralo oa mabili a nang le litekanyo tse habeli, o nolofalletsang ho ferekana le ho hasana ha lipululana.

Kopo: E loketse melapo e phahameng ea ho qhibiliha (habeli - rotor degassing thepa).

Mofuta oa A

Mofuta oa C

Silicon Nitride Lisebelisoa tsa Ceramic Melemo e totobetseng

Bophelo bo bolelele ba tšebeletso le litšenyehelo tse tlaase tsa tlhokomelo

Ka lebaka la matla a mocheso o phahameng, khanyetso e matla ea mocheso oa mocheso, le khanyetso e ntle ea kutu ea li-ceramics tsa silicon nitride, bophelo ba bona ba ts'ebeletso hangata bo fihla nako e fetang selemo, kahoo ba fokotsa litšenyehelo tsa ho nchafatsa le ho li lokisa.

Ha ho na tšilafalo ea aluminium e qhibilihisitsoeng

Silicon nitride e na le metsi a tlase ho litšepe tse qhibilihisitsoeng 'me ha e sebetsane le aluminium e qhibilihisitsoeng. Ka hona, e ke ke ea etsa hore tšilafalo ea bobeli e be aluminium e qhibilihisitsoeng, e leng thuso e kholo bakeng sa ho tsitsisa boleng ba lihlahisoa tse entsoeng ka tšepe.

Ha bonolo ho kenya le ho hlokomela

Silicon nitride ceramics e ka boloka matla a feto-fetohang a fetang 500MPa le khanyetso e ntle ea mocheso o tlase ho 800 ℃. Ka hona, botenya ba lerako la sehlahisoa bo ka etsoa hore bo be bobebe. Ho phaella moo, ka lebaka la ho ba le metsi a tlaase ho litšepe tse qhibilihisitsoeng, ha ho hlokahale hore ho sebelisoe seaparo sa holim'a metsi, e leng se etsang hore ho be bonolo ho kenya le ho boloka lisebelisoa.

Lethathamo la Papiso ea Litšenyehelo-Ts'ebetso ea Lisebelisoa tse Tloaelehileng tsa ho Koaheloa ho Indasteri ea Aluminium Processing

| Sehlopha | Index | Silicon nitride | Tšepe ea ho Lahlela | Graphite | Reaction-Sintered SiC | Carbon-Nitrogen Bonded | Aluminium Titanate |

|---|---|---|---|---|---|---|---|

| Tube ea Tšireletso ea Heater | Karolelano ea Bophelo | >10 | - | - | 3–4 | 1 | - |

| Karolelano ea Theko | >10 | - | - | 3 | 1 | - | |

| Litšenyehelo-Ts'ebetso | Phahameng | - | - | Mahareng | Tlase | - | |

| Phahamisa Tube | Karolelano ea Bophelo | >10 | 1 | - | - | 2 | 4 |

| Karolelano ea Theko | 10–12 | 1 | - | - | 2 | 4–6 | |

| Litšenyehelo-Ts'ebetso | Phahameng | Tlase | - | - | Mahareng | Mahareng | |

| Rotor ea ho hloekisa | Karolelano ea Bophelo | >10 | - | 1 | - | - | - |

| Karolelano ea Theko | 10–12 | - | 1 | - | - | - | |

| Litšenyehelo-Ts'ebetso | Phahameng | - | Mahareng | - | - | - | |

| Ho tiisa Tube | Karolelano ea Bophelo | >10 | 1 | - | - | - | 4–5 |

| Karolelano ea Theko | >10 | 1 | - | - | - | 6–7 | |

| Litšenyehelo-Ts'ebetso | Phahameng | Tlase | - | - | - | Mahareng | |

| Thermocouple Protection Tube | Karolelano ea Bophelo | >12 | - | - | 2–4 | 1 | - |

| Karolelano ea Theko | 7–9 | - | - | 3 | 1 | - | |

| Litšenyehelo-Ts'ebetso | Phahameng | - | - | Mahareng | Tlase | - |

Customer Site

Setifikeiti sa Feme

E tšeptjoa ke Baetapele ba Lefatše - E sebelisoa linaheng tse 20+