Crucible bakeng sa Foundry bakeng sa Melting Metals

Likarolo tsa Bohlokoa

Tsa rona Crucibles bakeng sa Foundryipabola maemong a feteletseng, e mamella mocheso ho fihlela1600°C. Thepa ea silicon carbide e netefatsa ho hanyetsa mocheso o motle haholo, ho bolelang hore ba khona ho sebetsana le liphetoho tse potlakileng tsa mocheso ntle le ho phatloha. Ho feta moo, thepa ea inert e fokotsa tšilafalo - e loketseng ho lahla tšepe e hloekileng haholo.

Melemo Ho Fetisa Baphadisani

- Nako e telele:E etselitsoe ho phela nako e telele, li-crucible tsa rona li fana ka chelete e ngata ea ho boloka nako.

- Theknoloji e tsoetseng pele:Ho sebelisa mochini o nang le khatello e phahameng bakeng sa boima bo tšoanang le matla.

- Litšenyehelo:Ka bophelo ba lilemo tse 'maloa, ba fokotsa litšenyehelo tse akaretsang tsa ts'ebetso.

Lisebelisoa

Li-crucible tsena li bohlokoa bakeng sa lits'ebetso tse sebetsang ka litšepe tse se nang ferrous joalo ka aluminium, koporo le koporo, li li etsa hore li fetohe bakeng sa lits'ebetso tse fapaneng tsa indasteri, ho tloha ho metallurgy ho isa tlhahiso ea likhalase.

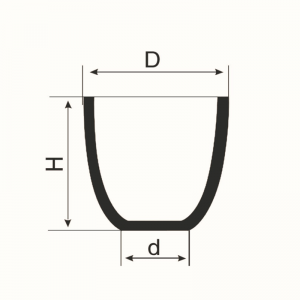

Litlhaloso tsa Tekheniki

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

FAQs

Ke mefuta efe ea litšepe eo nka e qhibilihisang ka lithupa tsee?

Li-crucible tsa rona li loketse aluminium, koporo, koporo, le tse ling.

Lithempereichara tsee li ka mamella mocheso o kae?

Li khona ho mamella mocheso ho fihla ho 1600 ° C, ho etsa hore li tšoanelehe bakeng sa mekhoa e matla ea ho qhibiliha.

O fana ka mokhoa oa ho itlhophisa?

E, re fana ka litšebeletso tsa OEM tse tsamaellanang le litlhaloso tsa hau.

Melemo ea Khampani

Re phahamisa lilemo tsa boiphihlelo indastering ea ho lahla. Boitlamo ba rona ba boleng, bo kopantsoeng le litharollo tse ncha le ts'ehetso ea bareki ba inehetseng, ho netefatsa hore u fumana lihlahisoa tse ntle ka ho fetisisa bakeng sa litlhoko tsa hau. Khetha ronaCrucibles bakeng sa Foundry'me u fetole phihlelo ea hau ea tšepe!