Reka Sic Crucible bakeng sa Ts'ebetso ea Sebopi sa Aluminium

LIEKETSENG LIHLAHISO

Superior Thermal Conductivity

Motsoako o ikhethang oa silicon carbide le graphite o netefatsa ho futhumala ka potlako le ka mokhoa o ts'oanang, ho fokotsa haholo nako ea ho qhibiliha.

Khanyetso e Feteletseng ea Mocheso

Motsoako o ikhethang oa silicon carbide le graphite o netefatsa ho futhumala ka potlako le ka mokhoa o ts'oanang, ho fokotsa haholo nako ea ho qhibiliha.

Khanyetso e tšoarellang ea Corrosion

Motsoako o ikhethang oa silicon carbide le graphite o netefatsa ho futhumala ka potlako le ka mokhoa o ts'oanang, ho fokotsa haholo nako ea ho qhibiliha.

LIEKETSENG MOKHOPO

| Graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Boima ba bongata / g·cm⁻³ | 2.20 |

| Ho bonahala ho porosity / % | 10.8 |

| Matla a ho pshatla/MPa (25℃) | 28.4 |

| Modulus of rupture/ MPa (25℃) | 9.5 |

| Mocheso o hanyetsanang le mollo/ ℃ | >1680 |

| Mocheso oa ho tsikitlana / Mehla | 100 |

| No | Mohlala | OD | H | ID | BD |

| 36 | 1050 | 715 | 720 | 620 | 300 |

| 37 | 1200 | 715 | 740 | 620 | 300 |

| 38 | 1300 | 715 | 800 | 640 | 440 |

| 39 | 1400 | 745 | 550 | 715 | 440 |

| 40 | 1510 | 740 | 900 | 640 | 360 |

| 41 | 1550 | 775 | 750 | 680 | 330 |

| 42 | 1560 | 775 | 750 | 684 | 320 |

| 43 | 1650 | 775 | 810 | 685 | 440 |

| 44 | 1800 | 780 | 900 | 690 | 440 |

| 45 | 1801 | 790 | 910 | 685 | 400 |

| 46 | 1950 | 830 | 750 | 735 | 440 |

| 47 | 2000 | 875 | 800 | 775 | 440 |

| 48 | 2001 | 870 | 680 | 765 | 440 |

| 49 | 2095 | 830 | 900 | 745 | 440 |

| 50 | 2096 | 880 | 750 | 780 | 440 |

| 51 | 2250 | 880 | 880 | 780 | 440 |

| 52 | 2300 | 880 | 1000 | 790 | 440 |

| 53 | 2700 | 900 | 1150 | 800 | 440 |

| 54 | 3000 | 1030 | 830 | 920 | 500 |

| 55 | 3500 | 1035 | 950 | 925 | 500 |

| 56 | 4000 | 1035 | 1050 | 925 | 500 |

| 57 | 4500 | 1040 | 1200 | 927 | 500 |

| 58 | 5000 | 1040 | 1320 | 930 | 500 |

TS'EPISO TS'OANE

1. Tlhahiso e nepahetseng

graphite e phahameng-hloeka + premium silicon carbide + moemeli ea tlamellang.

.

2.Isostatic Pressing

Boima ba ho fihla ho 2.2g/cm³ | Mamello ea botenya ba lebota ± 0.3m

.

3.Mocheso o Phahameng oa Sintering

SiC particle recrystallization e etsa sebopeho sa marang-rang sa 3D

.

4. Ntlafatso ea Sefahleho

Anti-oxidation coating → 3 × e ntlafetseng ea ho hanyetsa kutu

.

5.Tlhahlobo e Matla ea Boleng

Khoutu e ikhethileng ea ho lata bakeng sa traceability e felletseng ea bophelo

.

6.Polokeho Packaging

Lera le monyang ho tsukutloa + Mothibelo oa mongobo + Mokotla o matlafalitsoeng

.

SEBELISA SEHLAHISO

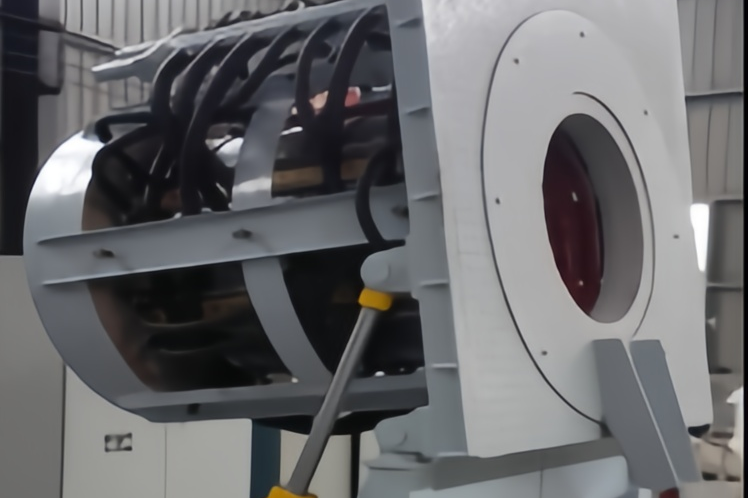

Sebōpi sa ho qhibilihisa Khase

Sebōpi se qhibilihang sa Induction

Resistance Melting Furnase

KE HOBANE'NG LE RE KHETHA

FAQS

Q1: Melemo ea silicon carbide graphite crucibles ke efe ha e bapisoa le li-crucible tsa setso tsa graphite?

✅Ho hanyetsa Mocheso o Phahameng: E ka mamella 1800 ° C nako e telele le 2200 ° C nako e khutšoanyane (vs. ≤1600 ° C bakeng sa graphite).

✅Nako e Telele ea Bophelo: 5x e betere ho hanyetsa mocheso oa mocheso, 3-5x nako e telele ea bophelo ba tšebeletso.

✅Zero Tšilafalo: Ha ho na khabone e kenang, ho netefatsa bohloeki ba tšepe e qhibilihisitsoeng.

Q2: Ke litšepe life tse ka qhibilihang ka har'a li-crucibles tsee?

▸Litšepe Tse Tloaelehileng: Aluminium, koporo, zinki, khauta, silevera, joalo-joalo.

▸Reactive Metals: Lithium, sodium, calcium (e hloka ho roala ha Si₃N₄).

▸Litšepe tse Refractory: Tungsten, molybdenum, titanium (e hloka vacuum / inert khase).

Q3: Na li-crucible tse ncha li hloka kalafo pele li sebelisoa?

Ho Tlama ho Baking: Butle-butle mocheso ho 300 ° C → tšoara lihora tse 2 (e tlosa mongobo o setseng).

Tlhahiso ea Pele ea Melt: Qhibiliha sehlopha sa lintho tse setseng pele (e etsa lera le sireletsang).

Q4: Mokhoa oa ho thibela ho phatloha ha crucible?

Le ka mohla u se ke ua lefisa lintho tse batang ka har'a crucible e chesang (max ΔT <400 ° C).

Sekhahla sa ho pholisa ka mor'a ho qhibiliha <200°C/hora.

Sebelisa li-crucible tongs tse inehetseng (qoba tšusumetso ea mochini).

Q5: Mokhoa oa ho thibela ho phatloha ha crucible?

Le ka mohla u se ke ua lefisa lintho tse batang ka har'a crucible e chesang (max ΔT <400 ° C).

Sekhahla sa ho pholisa ka mor'a ho qhibiliha <200°C/hora.

Sebelisa li-crucible tongs tse inehetseng (qoba tšusumetso ea mochini).

Q6: The minimum order quantity (MOQ) ke bokae?

Mehlala e Tloaelehileng: sengoathoana sa 1 (mehlala e fumaneha).

Meetso e Tloaelehileng: likotoana tse 10 (litšoantšo tsa CAD lia hlokahala).

Q7: Nako ea ho etella pele ke efe?

⏳Lintho tse ka har'a Stoko: E tsamaisoa ka hare ho lihora tse 48.

⏳Litaelo tse Tloaelehileng: 15-25matsatsibakeng sa tlhahiso le matsatsi a 20 bakeng sa hlobo.

Q8: U ka tseba joang hore na crucible e hlōlehile?

Mapetso> 5mm leboteng le ka hare.

Botebo ba ho kenella ka tšepe> 2mm.

Deformation> 3% (lekanya phetoho ea bophara ba kantle).

Q9: Na u fana ka tataiso ea mokhoa oa ho qhibiliha?

Li-curve tse futhumatsang bakeng sa litšepe tse fapaneng.

Calculator ea sekhahla sa phallo ea khase e inert.

Lithuto tsa video tsa ho tlosa slag.